DeLaval VMS is all about helping you make dairy farming more personal. More accurate. More profitable. With two models in the VMS series, we are able to treat each farm, each farmer, each cow, even each teat, individually, and to help you to create a better place to be for workers, cows, you and your families.

With two models available, the DeLaval VMS Series gives you options to create the voluntary milking system : that best matches your needs and goals of the farm. Both the VMS V300 and VMS V310 feature the core functionality that ensures your cows are milked to their full potential.

VMS series features:

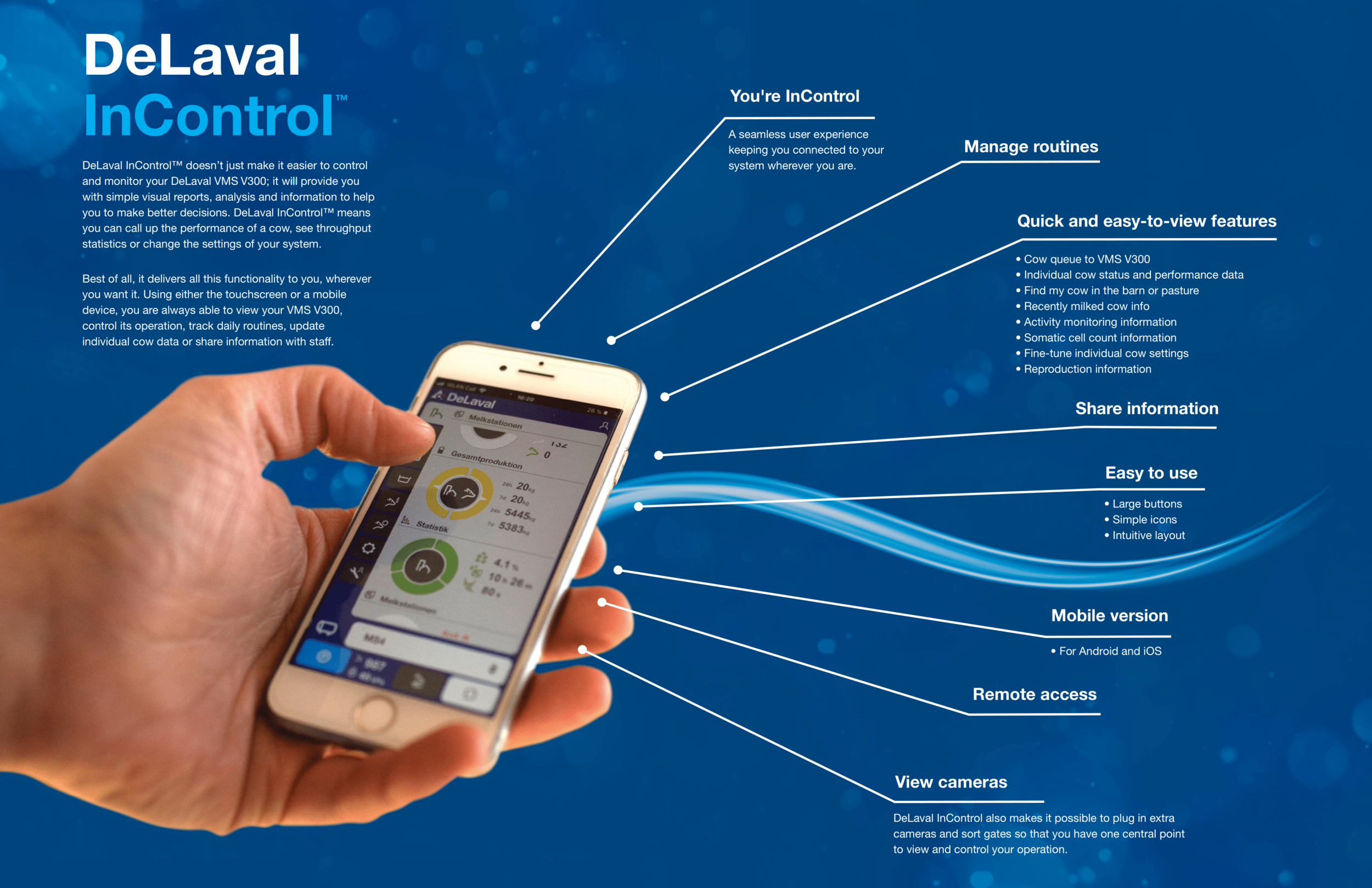

InControl™ – Seamless user experience keeping you connected to your system wherever you are.

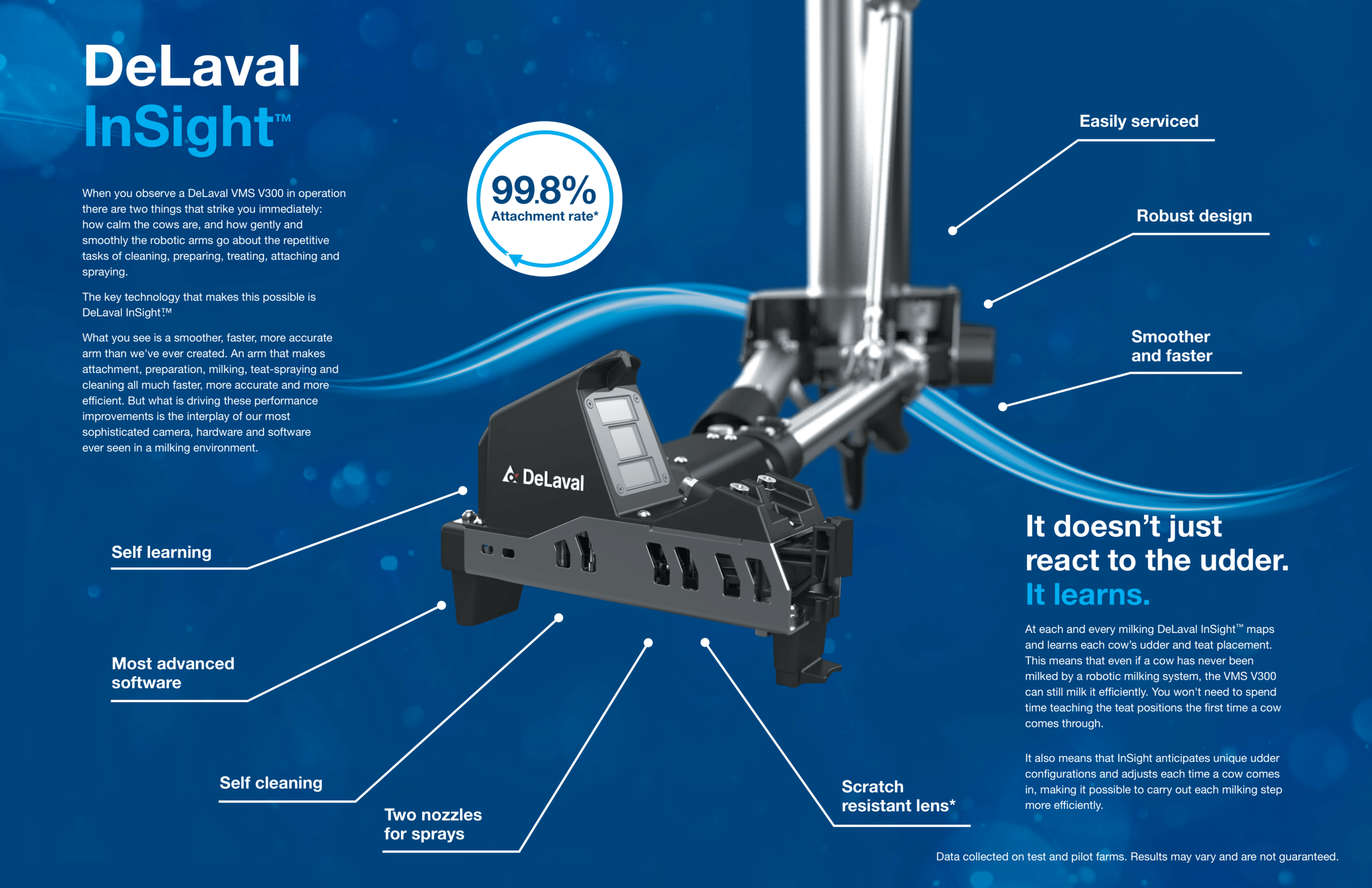

InSight™ – The most advanced camera and software combination delivers the fastest, smoothest milking.

PureFlow™ - The ultimate teat preparation delivered in its own individual cup.

DelPro™ Herd Management - A complete dairy farm management system that monitors, records and analyzes data to help you make those all important farming decisions

InService™ All-Inclusive - A customer program that provides service, consumables, advisory and everything in between on a contract system that provides farmers with the peace of mind that the system is running at peak performance.

Advisory Services - A network offering consultative services to dairy producers through three specialized, integrated teams: Facility Planning & Design, Farm Management Solutions, and Milk Quality & Milking Performance.

RePro™ - A complete reproduction management tool incorporated seamlessly into the milking process. Exclusive to the VMS V310.

ASPI CONCEPT is a fully automatic robot allowing the cleaning of slurry using suction.

CRD is a french company from France. For almost 28 years now, CRD teams have been working on farms to implement automatic solutions for slurry treatment and effluent management .

Improves animal hygiene, floor cleanliness

Advance speed up to 10m/min. Slope accepted: 8%

Adaptable, Flexible, Autonomous and available 24/7

Easy to use autopilot

Power consumption 250W/H

350L stainless steel slurry tank with automatic draining

70L stainless steel water tank with front and rear diffuser

Puncture-proof wheels

ALIM CONCEPT is a fully automatic and autonomous feed pusher robot.

The CRD “Alim’ Concept” Robot is a fully automatic and autonomous robot. It pushes back the fodder so that the animals have fresh food available 24/7.

This allows for a more serene herd, and an increase in fodder ingestion, significantly improving your production and profitability.<

– Improves animal welfare

– Time saving 15 hours / month for 3 passages / day. Labor reduction

– Increase in milk production 0.50 liter / cow / day

– Less feed loss between 45% and 55%

– Automatic skirt lifting

– Advance speed up to 10m/min. Slope accepted: 13%

– Power consumption 250W/H

– Puncture-proof wheels

– Easy to use Flexibility & Autonomous and available 24/7

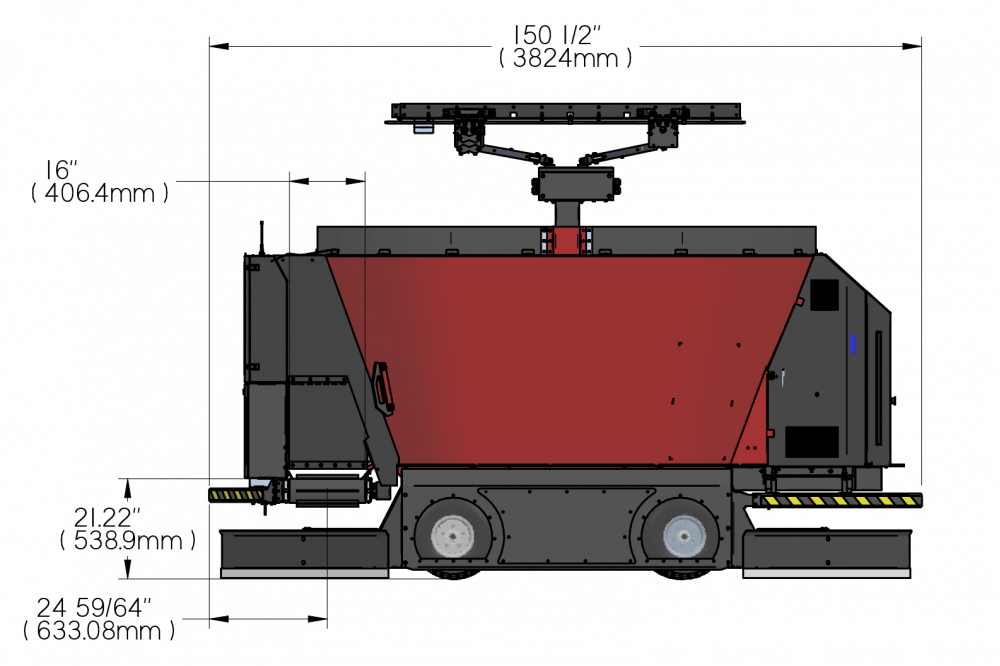

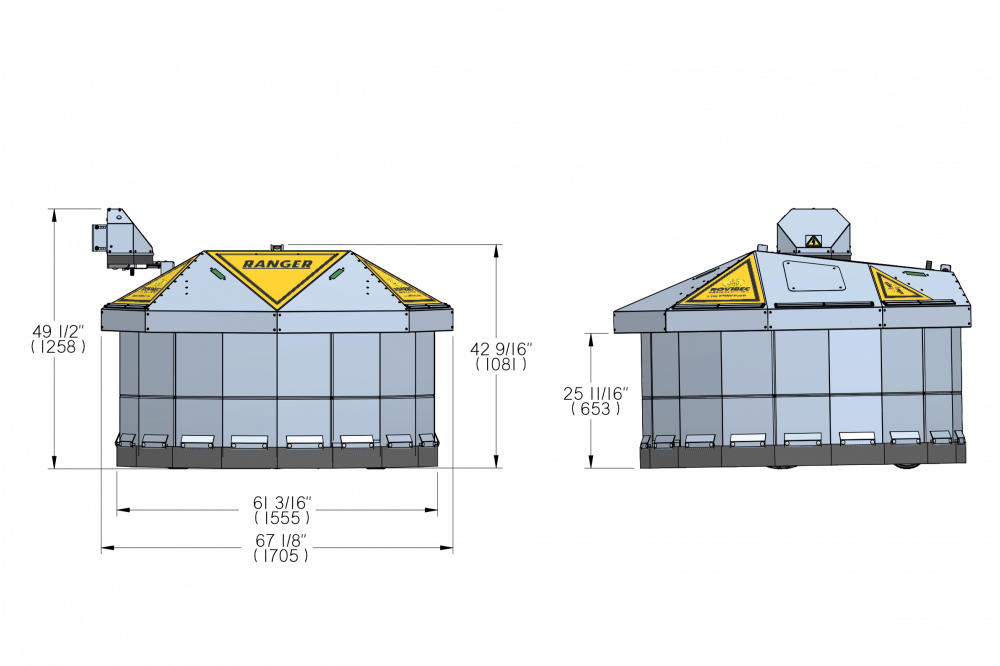

THE ROVER IS A COMPLETELY AUTONOMOUS FEEDING ROBOT OF 120 CU.FT. (3.4M3).

Why a feeding robot? Because it is capable of loading, mixing and of course distributing food to your animals without any human intervention!

Prepare up to 1000 Kg (2200 Lbs) Total Mixed Ration fully automated? Distribute your recipe to you animals in a precise and consistent way?

24/7 – YOU CAN COUNT ON YOUR ROVER!

Fast and efficient, this feeding robot also pushes food back.

The ROVER will therefore allow you to manage your feeding in an automated way for your different groups of animals, even when feeding several times a day! The advantage of the feeding robot is to feed animals with a fresh and adapted recipe more frequently. This food management aims to optimize herd health and productivity – while reducing associated labour.

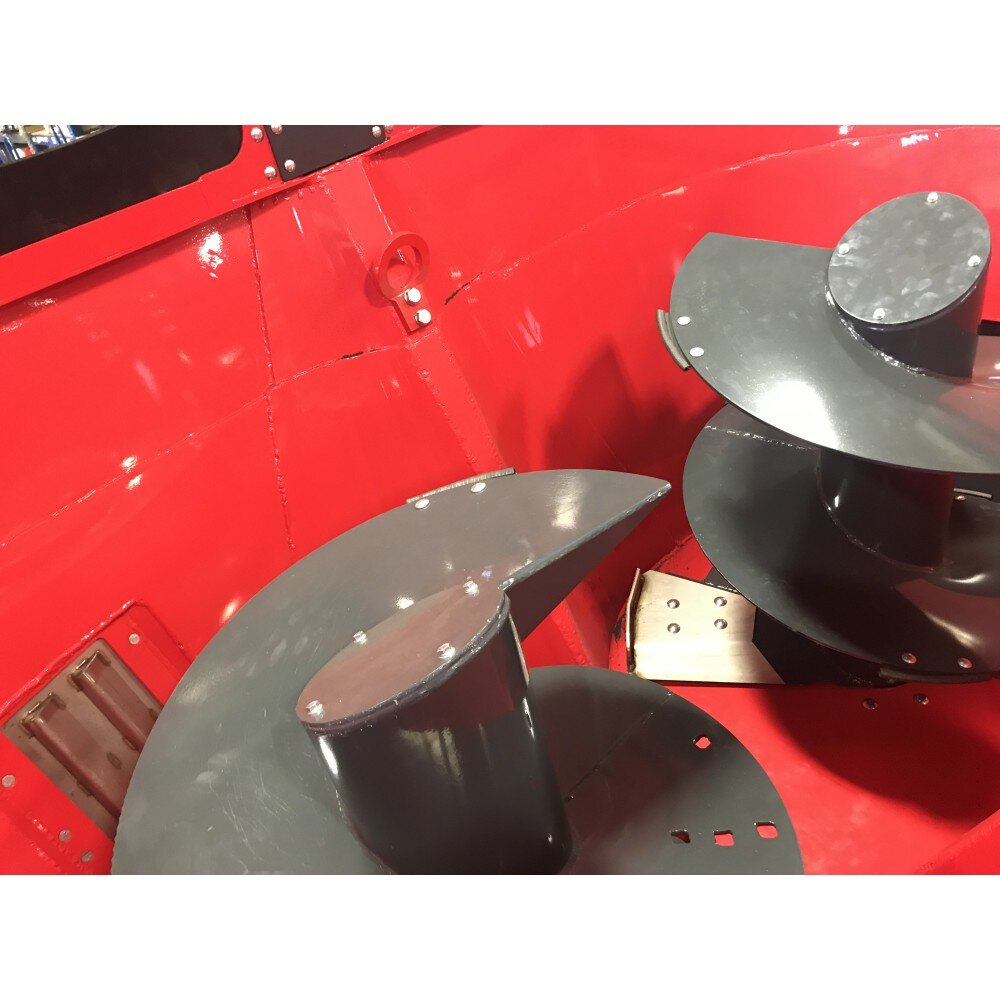

2 wear-resistant (Hardox) augers that can mix dry hay*

Stainless steel liner in the tub, for greater durability

Power supply via an conductor rail (240 or 380 V) that also guides the robot

Four-wheel steering driven by hydraulic power

2-sided discharge conveyor

Variable forward and discharge speed

An integrated management software for your parks and recipes: up to 16 departures, 16 recipes and 32 ingredients

A 2-years-warranty (parts and labour) as an option

HOW CAN YOU SAVE TIME AND IMPROVE EFFICIENCY?

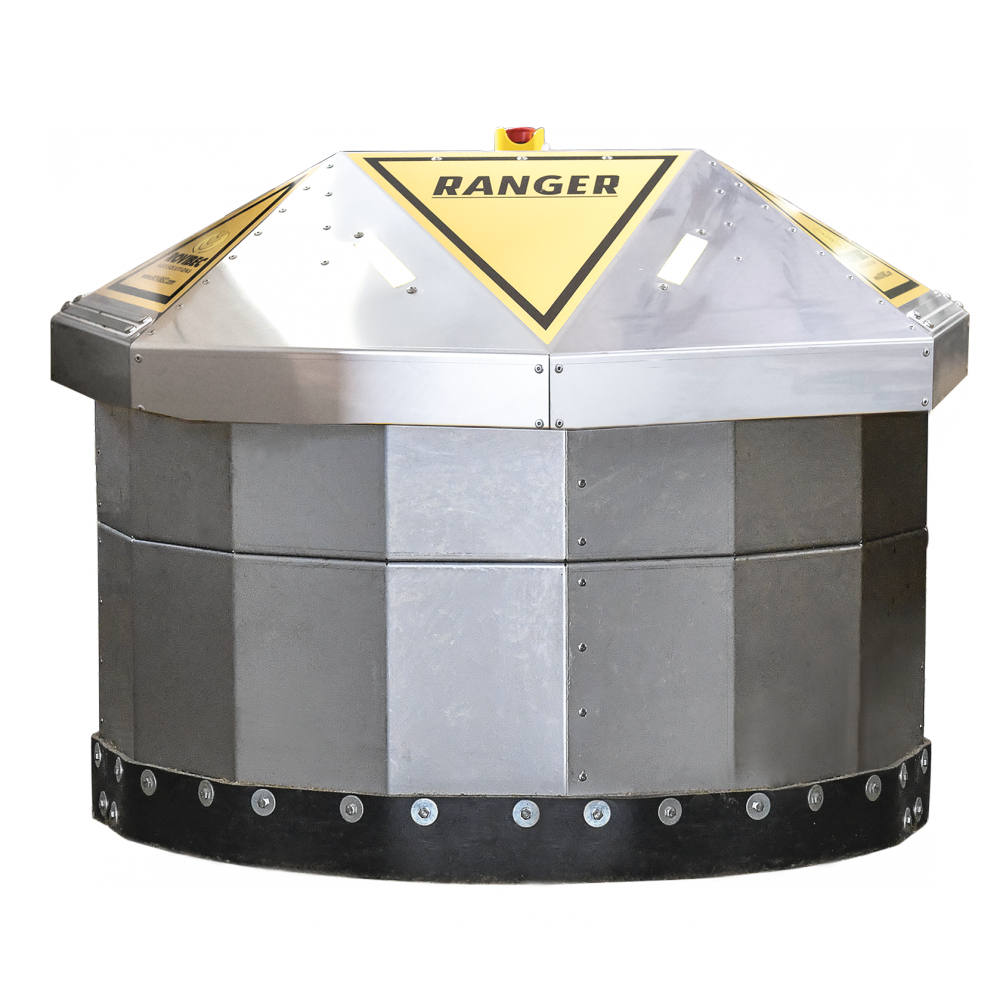

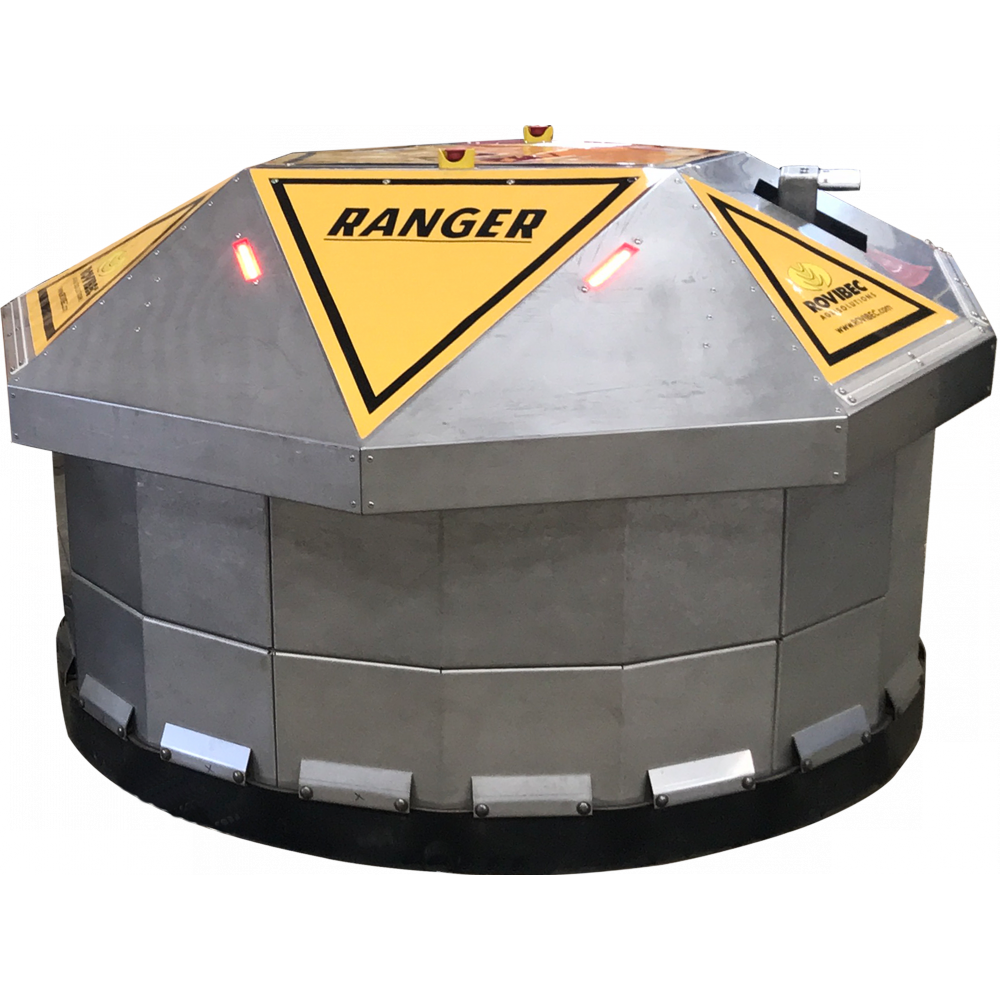

Investing in a feed pusher is probably a good solution. The Ranger automated feed pusher is a most profitable investment in that respect!

CAN YOU IMAGINE NEVER HAVING TO PUSH FEED TOWARDS YOUR CATTLE AGAIN?

LET THE ROVIBEC AUTOMATED FEED PUSHER MANAGE IT ALL BY ITSELF!

The Rovibec Ranger will follow its magnet strip up to 40 times per day. It will efficiently push food back to the fences. And it will even adapt to the quantity of food left in the curb!

The programmation is easy, the robot is reliable and does not require heavy maintenance. Once its job done, it will go back to its charging station until the next departure.

Because your cattle will have access to fresh food all day long, day after day. There will be an increased milk production and feed costs reduction.

The RANGER Feed pusher is the most efficient, the fastest and the most reliable on the market. Why choose another?

Self-guided feed pusher robot replaces the ration multiple times a day

Simple, efficient and reliable thanks to the ground-inserted magnet strip

Full consumption of ration Increases milk according to Journal of Animal Science

Automaticaly adapts the food pushing distance to the curb, without programation

No Risk of loss of control

Motorized rotating skirt increases pushing efficiencies

Low maintenance

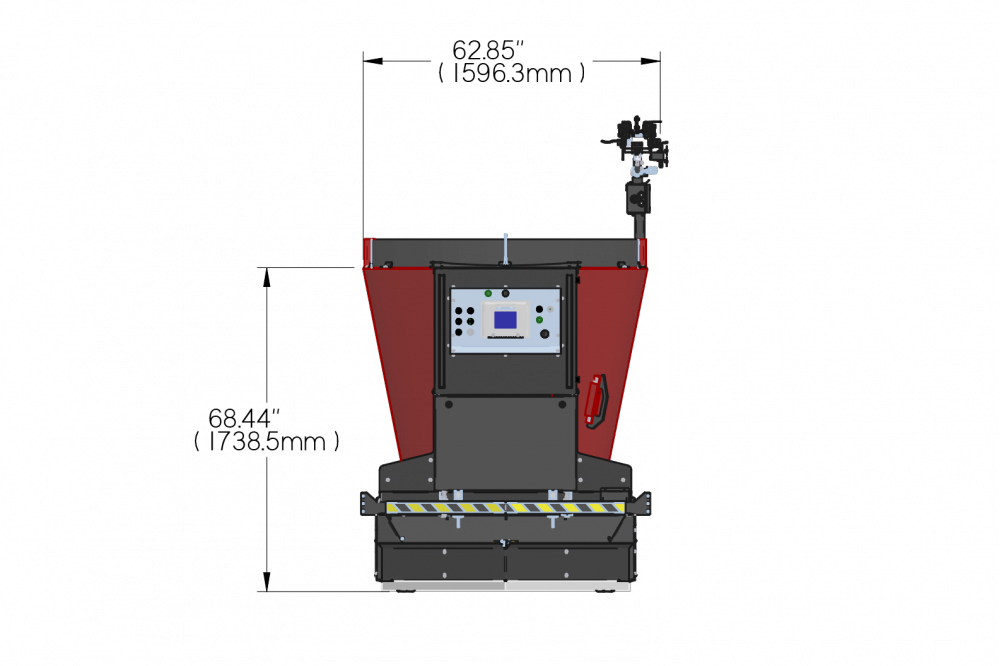

The RANGER COMMERCIAL is designed for very large herds and uses requiring more power than the standard version.

It pushes back more than 100 Lbs per foot (150 Kg per metre).

Self-guided feed pusher robot replaces the ration multiple times a day

Simple, efficient and reliable thanks to the ground-inserted magnet strip

Full consumption of ration Increases milk according to Journal of Animal Science

Automaticaly adapts the food pushing distance to the curb, without programation

No Risk of loss of control

Motorized rotating skirt increases pushing efficiencies

Low maintenance

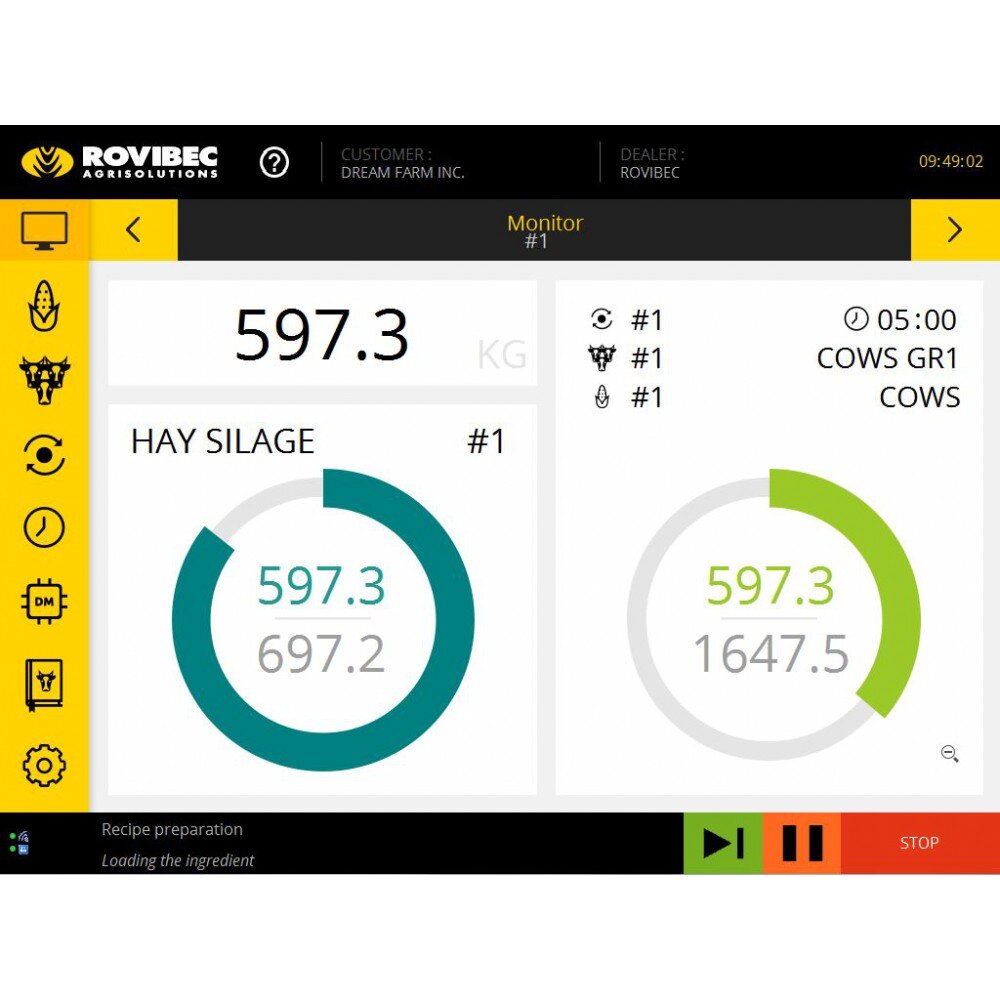

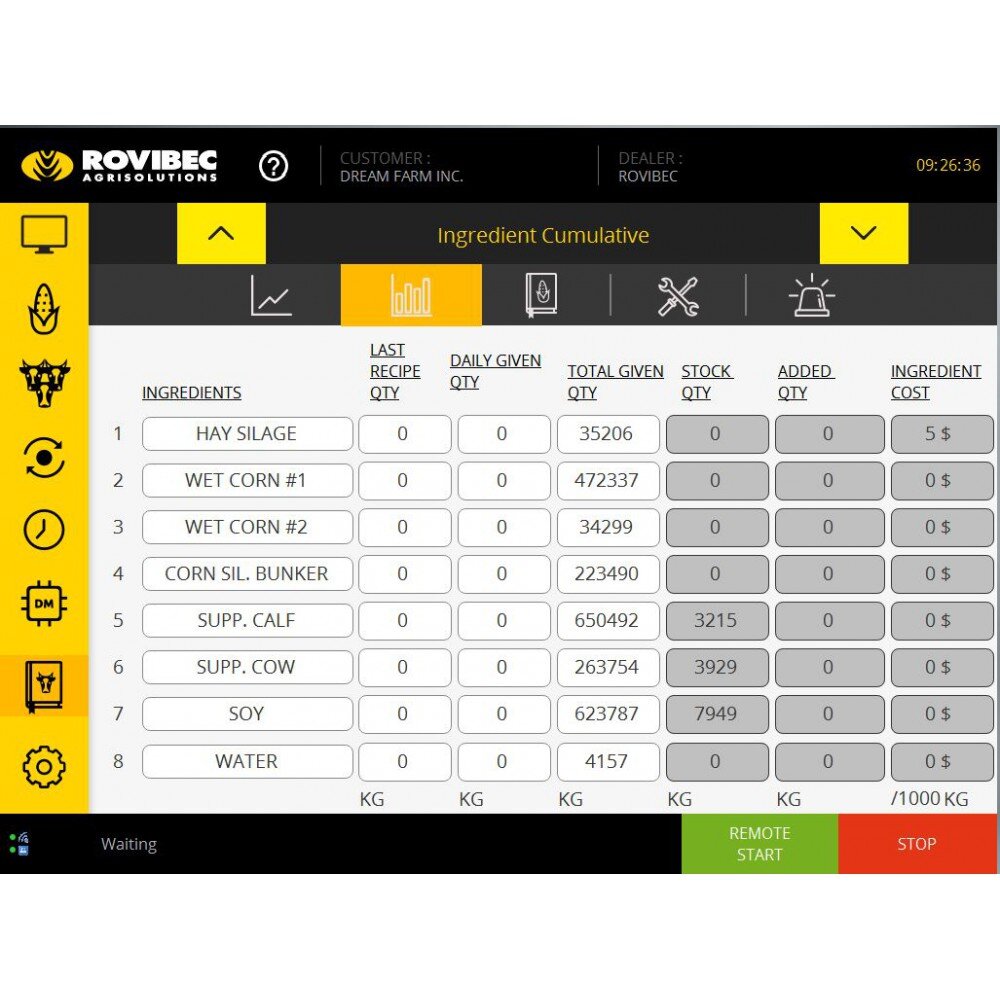

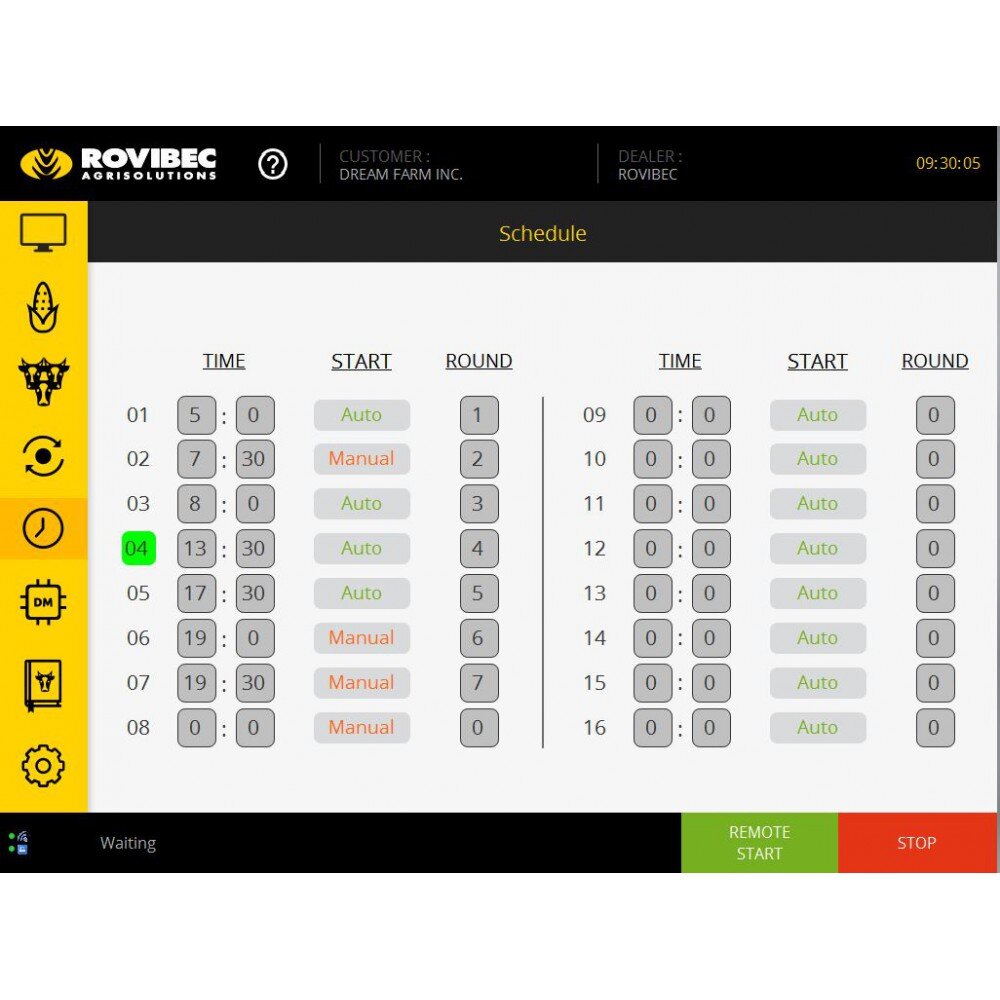

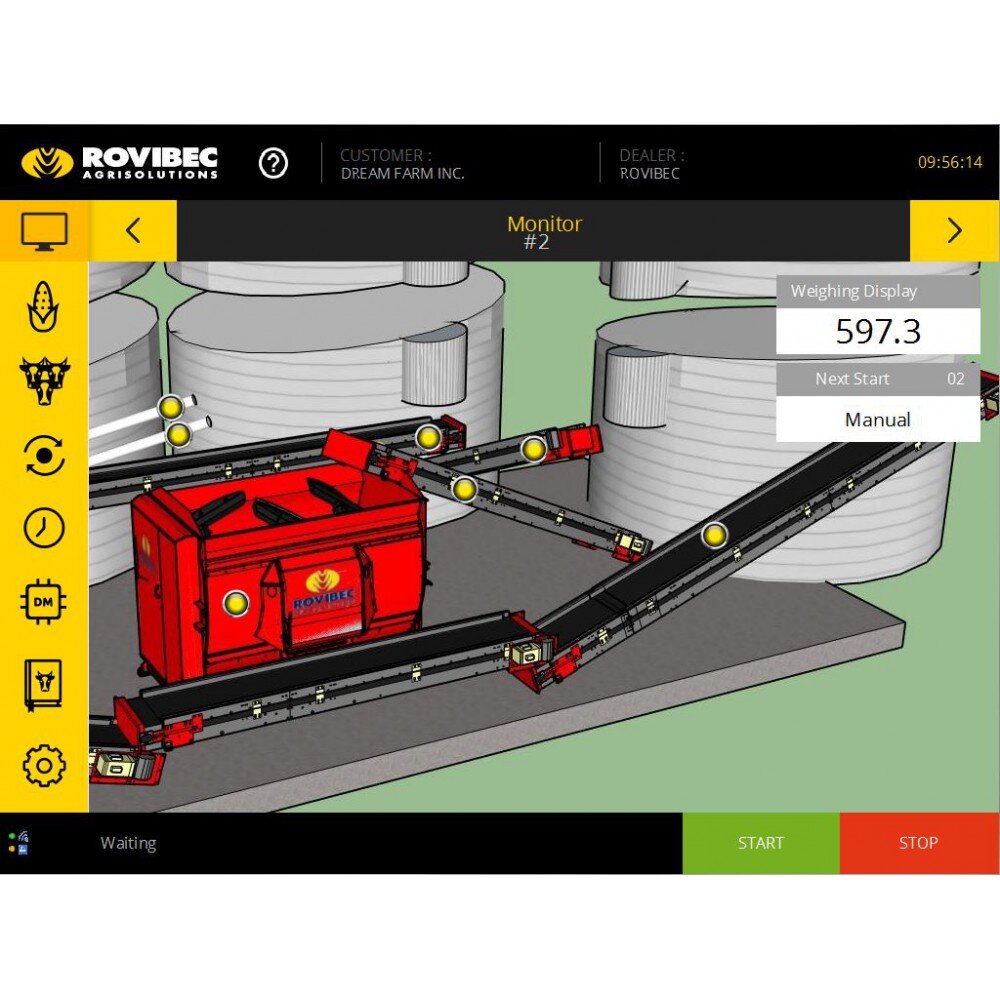

Are you ready to enter Agriculture 4.0?

The new generation of AGRIRATION 4.0 control panel takes you into a new management mode of your farm!

This is not just about automating your feeding equipments! You will have access to all the necessary information to manage your groups, receipes, stocks of ingredients, equipment maintenance… etc…

It is therefore the ideal solution to optimize the feeding of your animals. Your farm at your fingertips!

Access to all your data, at any time, via the Wifi network

Remote monitoring, in real time, via a clear and complete display of activities

Fluid and intuitiv navigation on a 15’TFT touch screen, a completely redesigned menu

Simplified ingredient management and dry matter management

Complete history of recipes and alarm provided

Inventory tracking

Operating time of equipments

Possibility to connect up to 5 cameras

Easy management of contact groups in case of emergency: contact by email or text messages

Remote data sharing, with a nutritionist, a technician or any other specialist

Meets north-american and european certification standards (CSA, UL, CE)

Available in 240V-1PH ou 380V/600V-3PH